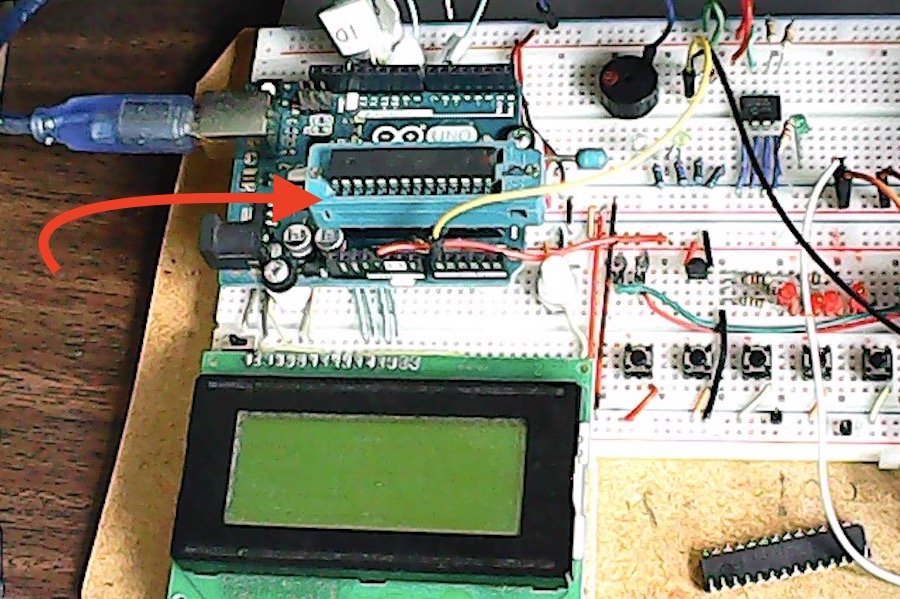

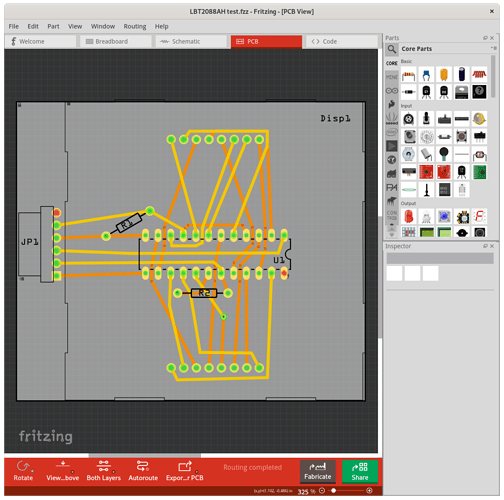

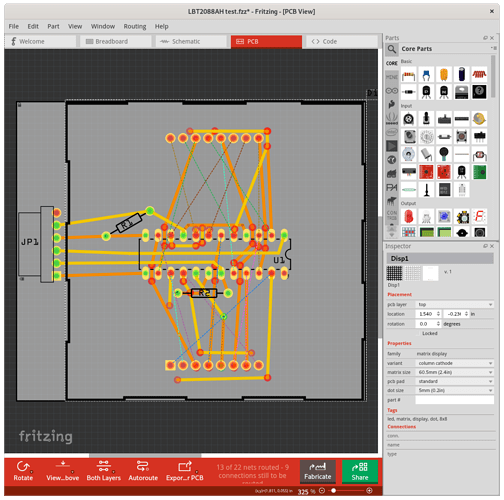

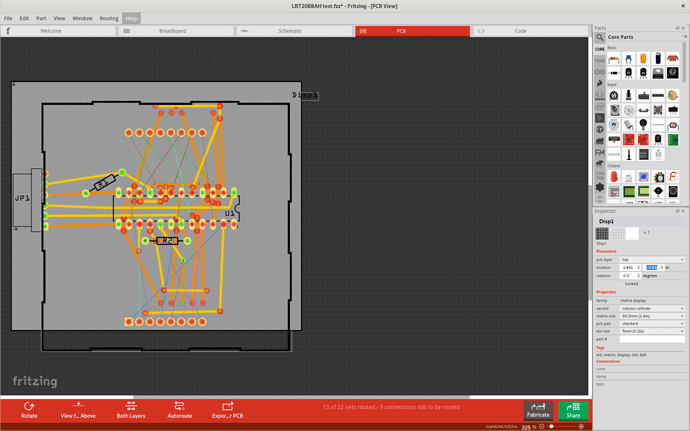

I had both forgotten I had turned that off, and did not know it would cause problems when updating the part. I turned it off on the breadboard view, so I could get the led matrix pins to align to the 2 separate breadboards. Turning the alignment grid size down as you did is another option. On the pcb, as you discovered, the space for the traces is tight, so again I turned of the grid alignment to gain (zoomed in) positioning freedom. I’ll have to adjust my process to use small grid spacing instead.

Also, that needs to go into usage documentation. If minor alignment / positioning differences are going to break part updating. Both as a strong recommendation to keep aligned to grid, and as a step to try if updating parts breaks things.

It is very hard to setup a breadboard numbering sequence that does not break when the size changes. Because the total number of pins changes, and the rule is that they are supposed to stay sequential.

If we could start at zero for the groups of five, and increment enough to handle the largest breadboard, then skip ahead to a convenient number (say 1000), and start a new sequence for the side connections, jumping by 100 for each group, then they should all be able to stay lined up. Otherwise you need a breadboard to breadboard pin mapping, similar to what is used for updating obsoleted parts.

Normally I would say you need that mapping for every breadboard, to every other breadboard. But, mapping each breadboard to that theoretical breadboard, matching the numbering pattern suggested above with gaps, would allow a 2 step mapping to work. So, define a fake breadboard with 200 groups of 5, and 8 groups of 100 (to handle the breadboards with the split in the middle of the side groups), with numbering from 0 to 1799, and map the connections of every real breadboard to that. That mapping could be shortcut drastically, if there was a way to specify the start and length of a sequential sequence. For the half+ breadboard, map

0 to 0, and continue for 150 entries, map 150 to 500, and continue for 150 entries, map 300 to 1000 and continue for 25 entries, map 325 to 1100 and continue for 25 entries, map 350 to 1200 and continue for 25 entries, map 375 to 1300 and continue for 25 entries. That would be a lot shorter than doing 400 pin mapping entries. Because the pattern is consistent that could even be reduced to just [0, 150, 300, -1, 325, -1, 350, -1, 375, -1], specifying the starting connection number for each connected group (of groups), with “-1” because the side groups are not split. With the right code, [150, 25, -1] is enough.

To improve that, might need an offset value, for how far the side groups are offset from the 0 row. Though simple centering should be very close (and a pain when that does not land on the 0.1 inch grid).

That can be used to match pins of a breadboard to any larger breadboard (up to 100 rows long). The other direction, there will be some truncation. Bonus if you (user) can specify an offset, so the middle of the bigger breadboard maps to the smaller one, instead of starting from the end.

Same kind of issues with strip boards, but I don’t think a general solution is possible for them. There are too many different connection patterns to create a general mapping.

for me the contour layer is empty:

for me the contour layer is empty: